Calibre 3DThermal was developed to meet the challenges of 3D-IC architectures where heat dissipation control is a key requirement. It offers fast, accurate, powerful and comprehensive methods to identify and quickly solve complex thermal problems. The software provides the flexibility to start initial feasibility analysis with minimal effort and can later perform more detailed analysis considering metallization details and their impact on thermal considerations as more detailed information becomes available. This progressive approach allows designers to refine their analysis and apply fixes, such as floorplanning changes and adding stacked vias or TSVs to avoid thermal hotspots and/or dissipate heat more efficiently. This iterative process continues until the final assembly is complete, significantly reducing the risk of performance, reliability and manufacturing issues in the final realization of the solution.

Precise floorplanning is important as it touches on the essential design step where the architectural decisions for a very large-scale integration (VLSI) design are evaluated. It deals with things like chip areas, delays and ”traffic jams” caused by wiring, providing crucial feedback to the design process.

Comprehensive understanding of the 3D IC device

Delivering thermal analysis at this advanced level requires a comprehensive understanding of the 3D-IC assembly. Waiting until assembly is complete to identify and correct errors can seriously disrupt design schedules, but Calibre 3DThermal mitigates this risk through automation and integration, allowing designers to iterate thermal analysis at whichever design stage they are working on.

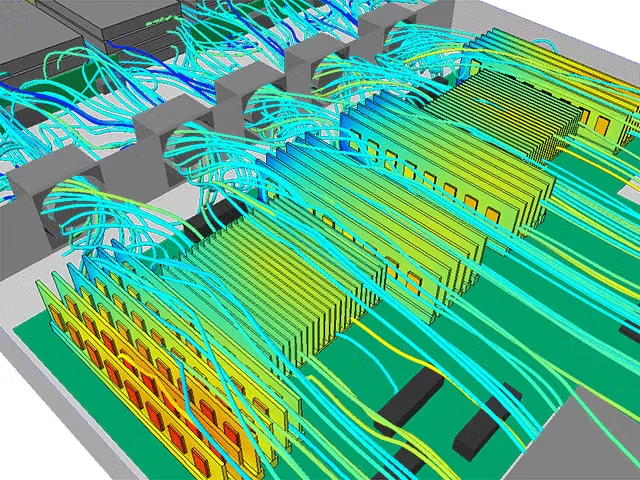

Calibre 3DThermal embeds a custom version of Siemens Simcenter Flotherm software solver engine to create accurate chiplet-level thermal models for static or dynamic simulation of entire 3D-IC devices. Debugging is streamlined through the traditional Calibre RVE software results viewer, which is already integrated into a wide range of IC design tools. The integration of these powerful tools results in an efficient thermal analysis solution tailored to the specific needs of 3DIC designers.

Like all Calibre products, 3DThermal integrates seamlessly with a range of industry-leading design tools from both third parties, as well as with Siemens software including the recently announced Innovator3D IC software. In all design flows, Calibre 3DThermal captures and analyzes thermal data across the entire design lifecycle.

Cooperation with UMC

In a collaboration, Siemens has joined forces with United Microelectronics Corporation (UMC) to deploy an innovative thermal analysis workflow for UMC customers powered by Caliber 3DTermal. Tailored specifically for UMC’s wafer-on-wafer and 3D-IC technologies, this breakthrough software has been validated and is scheduled for availability to UMC’s global customer base shortly.

“As the semiconductor industry grapples with escalating thermal challenges, particularly regarding heat dissipation and thermal gradients in advanced 3D IC technology, UMC continues to provide effective solutions,” said Osbert Cheng, VP of Device Technology Development and Design Support at UMC, and added:

”Through our collaboration with Siemens and the implementation of Caliber 3Dthermal, we will be able to offer our customers a comprehensive thermal analysis capability, enabling them to address critical thermal c once and optimize their designs for improved performance and reliability.”