ANALYSIS. Today’s article on engineering.com covers what’s happening in the PLM field for the Aerospace & Defense (A&D) industry.

The issue is a hot topic not only in the wake of the dramatic coronavirus’ effects, but also related to technological developments, climate concerns and a world that seems to be heading into a massive transition from fossil-fueled to electric power generation.

A TOUGH SITUATION

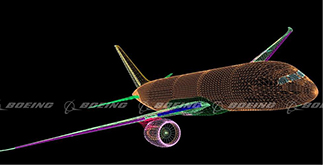

How is product development affected, especially in civil aviation, when financial resources are radically reduced? What does the way forward look like when it comes to investments in digital tools and the corresponding methods to reach concepts such as digital twins and threads, model-based system development, muliti-view BOM’s, secure collaboration and others? Can PLM and new processes help when money is becoming a scarce resource in the A&D industry that in 2019 spent more than $4.6 billion on PLM related areas?

“It is a tough situation,” says Jim Roche. “But advances in terms of sharper processes, new methods and corresponding tools are foundational regardless of the economic cycles.”

Jim Roche is CIMdata’s A&D practice director, and a well-known profile in the segment. He is also a member of CIMdata’s Aerospace & Defense PLM Action Group (AD PAG) initiative.

Meet him in today’s article and A&D industry analysis on engineering.com.

Click on the headline below to read the full article on www.engineering.com:

PLM and Digital Threads Are Not Quick Fixes When the Coronavirus Downturn Hits the Aerospace & Defense Industry