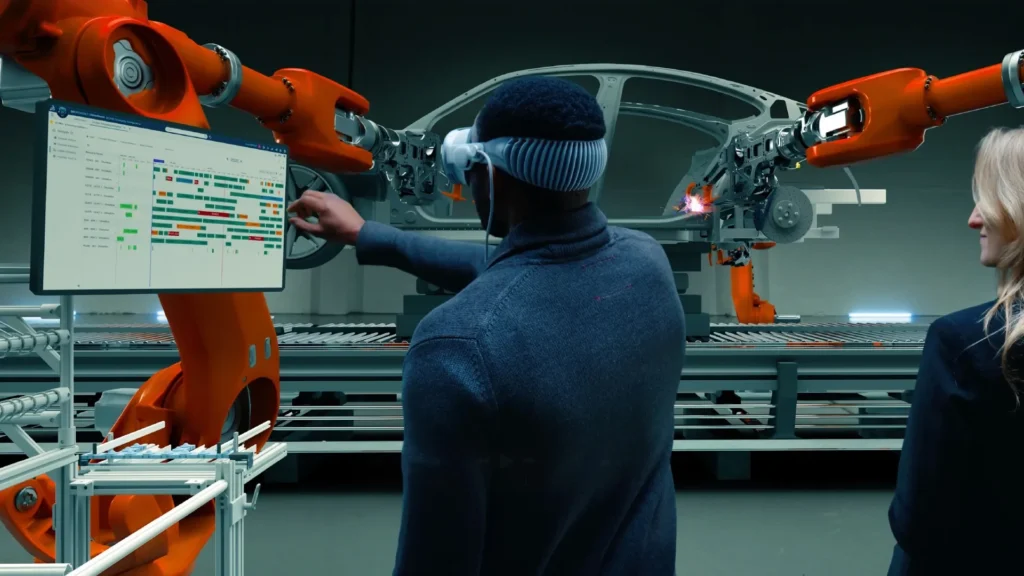

To realize this immersive solution, Dassault Systèmes has collaborated with Apple to integrate Apple Vision Pro into the next, seventh generation of the 3DEXPERIENCE platform.

“The deep engineering collaboration between Dassault Systèmes and Apple has brought together the best of both platforms to deliver this magical experience,” claims Daloz. With the 3DLive app, virtual twins created on the 3DX platform will be able to “jump off” the screen and into a user’s physical space, enabling real-time visualization and team collaboration in lifelike environments.

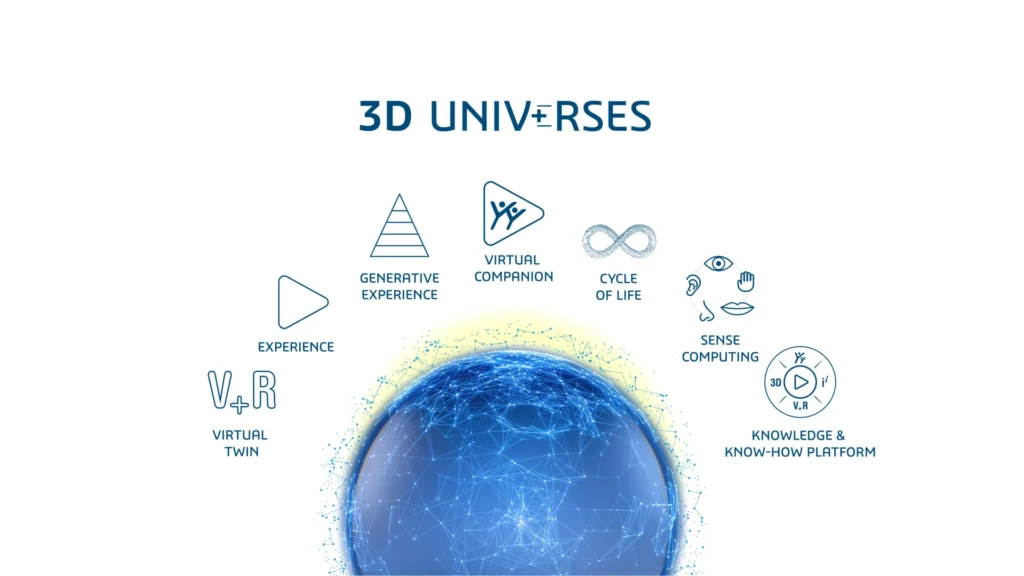

“Unveiling the Power of 3D UNIV+RSES”

“Our engineering collaboration with Apple represents a bold step forward that reveals the power of 3D UNIV+RSES, where 3D is a universal language for a new world that combines the real and the virtual,” Prisner, continued, explaining that, “This is the core of our next-generation representation of the world. The broad and growing adoption of the 3DEXPERIENCE platform by our customers makes this collaboration a unique value proposition for our vast, highly diversified customer base, who see the high potential of 3D UNIV+RSES to collaborate and train our next-generation AI-based experiences on their own virtual twin dataset.”

She further points out that the new solution represents a unique and powerful way to model, simulate, manufacture, train and operate, delivering value across all industry sectors and roles:

“This enables users to leverage the full potential of 3D UNIV+RSES and spatial computing to quickly adapt to market demand, ensure scientifically accurate product quality, accelerate workforce training, collaborate and share knowledge and know-how.”

Apple’s VP of the Vision Products Group, Mike Rockwell, adds that Apple Vision Pro continues to push the boundaries of what is possible with spatial computing and transforms the way people work in key industries:

“We are excited to partner with Dassault Systèmes to bring spatial capabilities and engines to the 3DEXPERIENCE platform. It empowers 3D designers to bring life in ways never before possible.”

To access these immersive experiences and design tools, enterprise customers will be able to download Dassault Systèmes’ new 3DLive app for Apple Vision Pro this summer. In addition, Dassault Systèmes is today (2/26/2025) releasing a new Apple Vision Pro app – HomeByMe Reality – that allows users to imagine, explore and visualize their home interiors and options, from the comfort of their own home, a furniture store or in a showroom. The app can also allow people to virtually “walk around” properties.

AI was the theme of the event – Daloz’s strong points

Generally speaking, AI was unsurprisingly the thematic theme of the 3DX World event. Pascal Daloz set the tone during his stage performance in Houston:

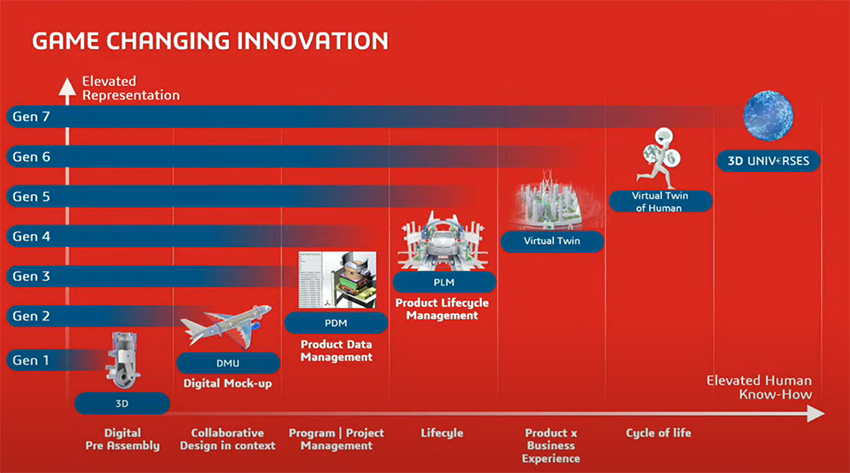

“This new generation puts artificial intelligence at the center of everything we do,” Daloz said, adding, “3D UNIV+RSES is the seventh generation representation of digital 3D tools in the product development world introduced by Dassault Systèmes.”

He also noted at a press conference that the 3D UNIV+RSES concept is conceptually close to Meta’s industrial metaverse as well as NVIDIA’s Omniverse, which PLM&ERP News has described in several reports.

“But a weak spot generally is that the metaverse is a virtual world that is not connected to reality,” Daloz said in a comment, pointing out that with 3D UNIV+RSES, the connection between the physical and the virtual will become a realty. He added that NVIDIA’s Omniverse right through is such a virtual world, while 3D UNIV+RSES offers “the ability to navigate across different scales and disciplines, something that Omniverse cannot do.”

Daloz certainly has relevant weight in his view. What we see ahead is the path from traditional manufacturing to digital twins as the basis for what is to be done. According to the old development model, everything from developing cars and airplanes to washing machines and factory facilities are complex and costly design projects of varying scope. It has involved hundreds or thousands of CAD drawings and simulation sessions with lots of engineers involved and thousands of hours of meetings – without being able to be sure that everything would work according to plan.

With the solutions that Dassault is now bringing to the table as pillars of its seventh generation product development concept, major parts of the conditions to change the picture are, or will be, in place. But DS is far from alone in presenting and developing metaverse solutions. However, when Daloz and DS chairman Bernard Charles sketch the idea of digitally stepping into cars, driving them, manipulating designs, or experiencing and perhaps optimizing the functions, they are absolutely on track. As also is the case when they discuss how factory facilities can be studied and tested in terms of the layout of production lines or how machines might work – everything before it physically exists – is an equally valuable capability that lies within the plans and framework of industrial metaverses. In fact engineers and other operational employees already today can be trained in the digital environments, suppliers can be shown around facilities they are supposed to serve, etc.

Even more attractive may be that you can use these digital concepts to communicate with the customers of the products you intend to develop.

Interest grows as the technology matures

In short: using the Metaverse on a large scale is an inexorable path forward. The technology is maturing. And both interest and investments are growing. The big breakthrough for the industrial metaverses is close and AI has a central role. Daloz and Charles are absolutely right about this.

At the same time; the metaverse is in a time of transition right now and nothing will come as quickly as one might be led to believe when something new is presented. However, significant technologies such as 5G and edge computing are starting to fall into place and it is not a bold guess that AI will fill the metaverse worlds with steroids.

A backdrop is that the interest among the major players is high. According to a survey conducted by automation company Nagarro together with Visual Sweden, for example, 30 percent of Swedish industrial companies have started metaverse projects, and two out of three are investigating application areas.

AI in SOLIDWORKS

Speaking of AI, Daloz introduced in his keynote two new categories of AI-based services that Dassault calls, “generative experiences and virtual companions.”

- “Generative experiences,” he exemplified as, “AI-driven automations for assembly, requirements, design, testing and validations.

- While “Virtual Companions” were described as: “AI assistants that can help improve skills and speed up workflows.” One such companion, DS calls it “Aura,” is a chatbot that is currently available in the 3DSwym app on the 3DEXPERIENCE platform.

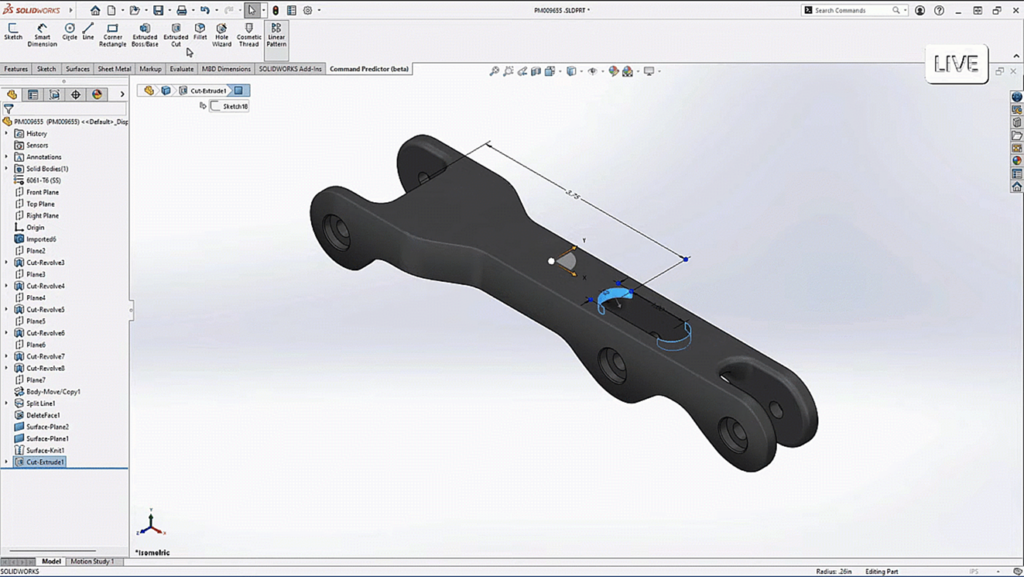

Of course, the AI theme also found its way more concretely to the SW community in SOLIDWORKS CEO Manish Kumar’s keynote. Some of these are already available while others are in the development or planning stages. But overall, there were a lot of AI goodies that directly appealed to 3D designers and engineers who rely on the SOLIDWORKS CAD platform as their primary design tool.

Among the things that made it onto this AI list were:

- Generative rendering, which will be able to quickly create custom product renderings.

- 3D models of a product that can be converted to a 3D mesh, ready for simulation.

- A “mesh-to-3D feature” that will eventually be able to transform those meshes into parametric 3D models.

“Whether you’re working with 3D scan data, imported mesh files, or legacy CAD models, this feature, once fully developed, will provide a seamless way to transition from complex mesh geometry to built-in parametric capabilities,” said Kumar.

Good stuff, of course, more on the technical enhancements in a coming article.