Solid Edge is generally used mostly in industries and areas such as machine development, higher education, automotive, industrial automation, electrical and electronic manufacturing. The program has also been ranked highly in several evaluations, for example Solid Edge received top rankings in 32 different categories in the Grid Report 2022 by G2. Solid Edge was then positioned as a leader in the category of CAD software for general purposes, product and machine design, 3D printing, simulation and CAE and more.

On the user level and in the press material around the new 2025 version Siemens exemplifies user reactions with Michael Orr, Design Drafter at Ariel Corporation who states that, “SE 2025 is very intuitive to use. With simplified and refined workflows, we can design with fewer keystrokes, allowing us to be more productive, while saving additional time,” he says, claiming the release exceeded expectations.

Solid Edge X – cloud-based solution with built-in PDM

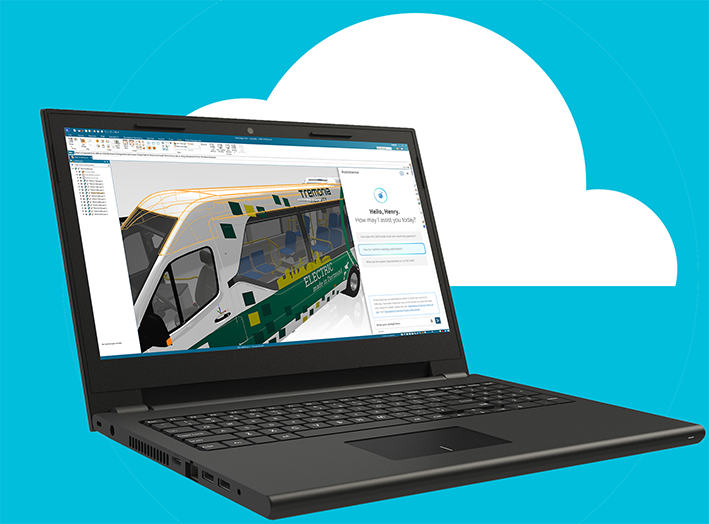

So, let’s take a look at the most exciting launch of all in the 2025 Solid Edge sphere: the SE X version. An important point is that it delivers the power of Solid Edge in a secure SaaS environment, offering the easy-to-use features of SE in a flexible, accessible experience. In the press release Siemens claims that, “Solid Edge X helps reduce IT complexity and costs, with automatic updates and secure access from any device. With cloud-based built-in data management, based on Siemens’ industry-leading PLM backbone, Teamcenter software and infrastructure, users can collaborate across engineering and manufacturing disciplines wherever and whenever needed.”

Included in Solid Edge X is new artificial intelligence which of course is hyper-current in these times; in this case we’re talking about (AI)-powered functionality that offers real-time assistance and helps minimize disruption to technical workflows. This new capability, available next year, provides in-app product help, allowing engineers and designers to stay focused on the task at hand and find the help they need, minimizing disruption and tailoring help to solve problems immediately.

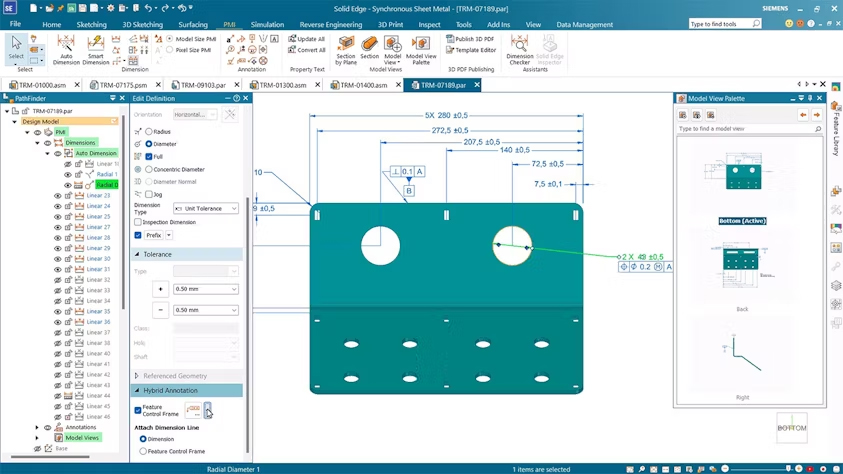

Model-Based Definition – MBD

MBD is an area that has grown strongly in recent years. The technology’s overall benefits are that it replaces traditional 2D drawings with 3D models, enabling greater efficiency, accuracy and clarity in the manufacturing process. With MBD, product information is conveyed through the 3D model rather than separate drawings, annotations and specifications. Because model-based definition annotations are standardized and shareable between programs, MBD eliminates manual re-entry of data from 2D drawings – reducing errors and time spent on design, manufacturing and inspection processes.

This development has been excellently reflected in Solid Edge 2025, which speeds up and simplifies the creation of model-based definition (MBD), how does it work?

The new hybrid annotation feature in Solid Edge 2025 enables engineers to insert dimensions and feature control frames into designs with an efficient, all-in-one workflow, supporting model-based definition and providing the tools to quickly and accurately detail 3D models. New feature control frames and updated surface texture symbols help users comply with ever-changing standards, while automatic dimensioning helps maintain consistency and minimize errors.

More news and improvements

Adaptability and customization: New customization options make it easier for users to tailor their Solid Edge experience and enjoy a personalized design environment. With features like redesigned vertical command bars and improved context toolbars, you can streamline your workflows and enjoy greater flexibility.

The new Discovery Center provides a centralized hub where users can access a wide range of resources, learning materials and free trials, available directly from the product, for a seamless experience

Elevated sheet metal design: Continuous improvements to Solid Edge’s industry-leading sheet metal capabilities streamline workflows and improve precision. Updates for the Solid Edge 2025 release include support for complex geometries, which offer improved bend calculation, making it easier to create accurate sheet metal parts. Bend deductions and bend allowances allow control of material conditions related to fabrication and tooling. New etch features now support bends and curved surfaces, automatically placing etch on all relevant surfaces, while improved bend support displays detailed properties and calculation methods.

Connect, collaborate, share – anytime, anywhere

Solid Edge includes tools that support integrated collaboration with the Teamcenter Share app, Siemens’ collaboration service, included as part of Siemens’ ”Xcelerator-as-a-Service offering.” Teamcenter Share allows users to collaborate on assemblies and track tasks seamlessly within Solid Edge, and create, edit and delete projects as needed. Data can be shared as needed using the service – which now supports data sets up to 500Gb.

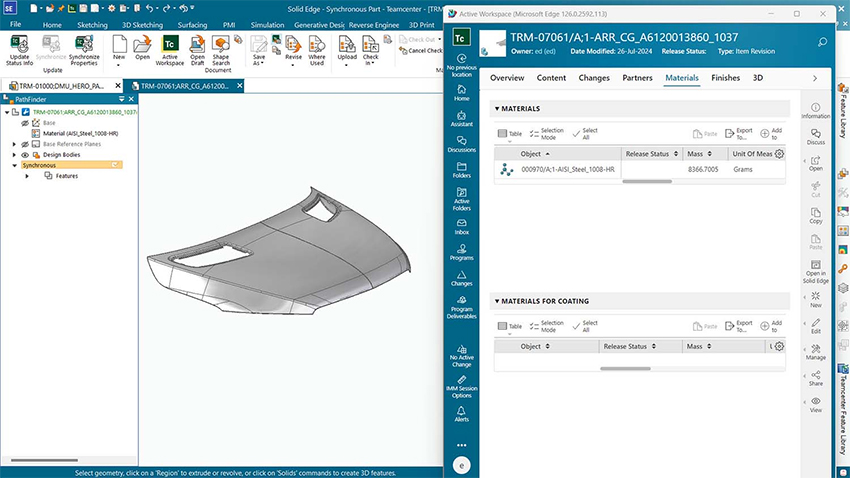

For organizations looking to advance their digital transformation, the latest Solid Edge updates also streamline operations when using integration with Siemens Teamcenter software for PLM. Managed data now opens up to 50% faster with accelerated download speeds to enable users to get up and running with complex datasets faster.

Also enhanced for this update is the ability to define and manage material definitions using the Integrated Material Management feature from Teamcenter. This enables customers to define managed material definitions, enabling control of the critical information for accuracy, consistency, traceability and security – leading to optimized material use, waste reduction and helping customers achieve their sustainability goals through accurate, environmentally sound material selection.

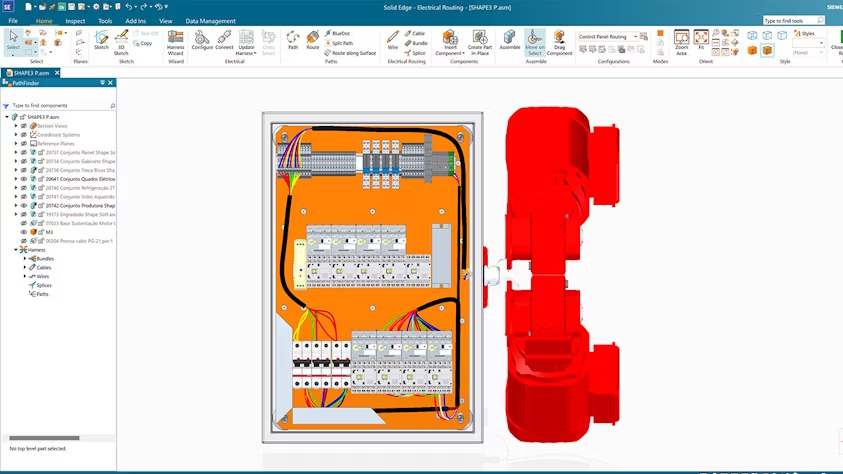

Electrical schematics with cloud-based Capital X

Solid Edge 2025 integrates with Capital Electra X software, a new cloud-based electrical design tool from Siemens that enables designers and engineers to create electrical schematics quickly and efficiently. Available on all devices, Capital Electra X delivers an intuitive and accessible platform to enhance electrical design capabilities – improving workflows and reducing overhead.

Improved simulation, analysis and CAM tools

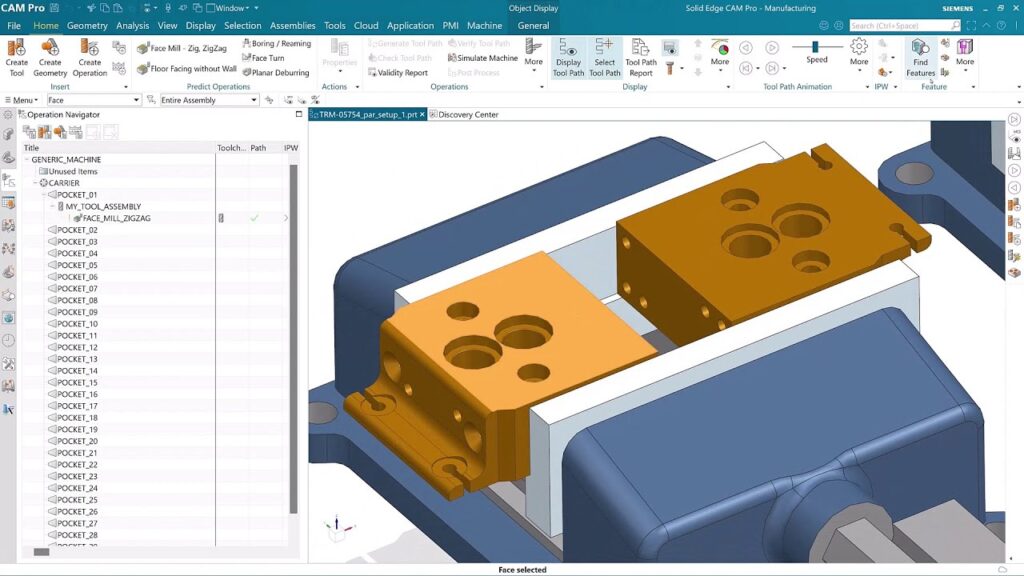

Smart and Simplified Machining: Solid Edge CAM Pro software delivers improvements to detail programming and machining performance with new smart assistance that automatically recommends the best operations, streamlines toolpath creation and simplifies the programming process, while advanced rapid roughing and zigzag milling features simplify offset roughing and face milling. Automatic hole processing also makes it easy to select prismatic features such as slots, steps and holes.

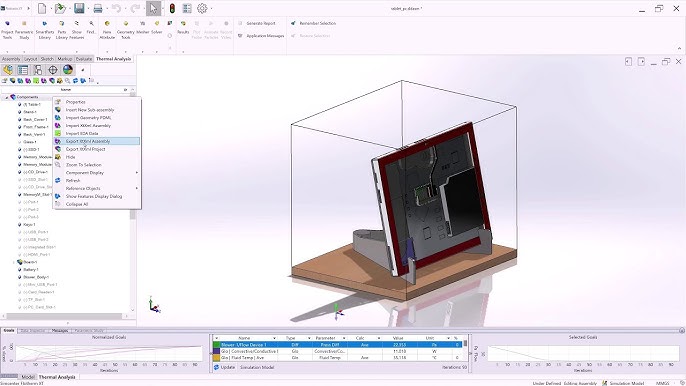

Simulation and analysis: things like faster mesh generation and access to advanced flow and heat simulation can be noted.

Integration with Simcenter FLOEFD for Solid Edge software has been improved, enabling direct import of complex CAD models for analysis, saving time in the simulation process. Simplified fluid flow and heat transfer analysis makes it easy to evaluate product performance under different conditions. Mesh generation for convergent, faceted and STL geometries is now even faster. With new templates and tools, it is easier and more streamlined to set up complex simulations.

Optimize design projects with NX compatibility and IFC file support

Interoperability between Solid Edge and NX software allows engineers to reuse data and work seamlessly with the software that best meets their needs. Easily transfer section views, advanced PMI, kinematic data and more between Solid Edge and NX. New enhancements support the import and export of International Foundation Class (IFC) file types, a standard in the building and construction industry, allowing users to store and exchange construction project information without translation.