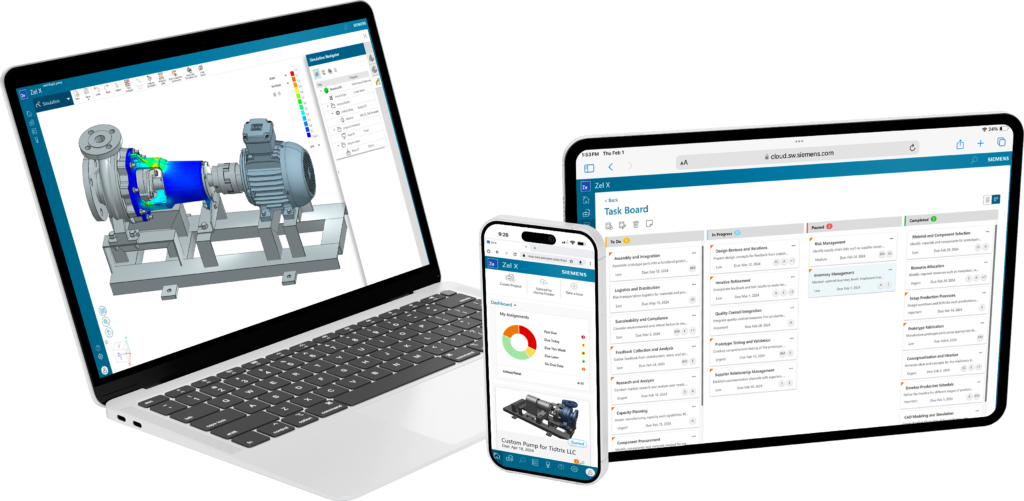

First, a few words about this key to faster and better digital collaboration throughout the product development process. Instantly accessible anytime, and on any device, Zel X provides cloud-based project storage and collaboration. All built on the same Teamcenter-based core platform common to the Siemens Xcelerator portfolio, which provides reliable data management capabilities to some of the world’s leading innovators along with data sharing and collaboration capabilities with the Teamcenter Share app. Zel X enables customers to unify their supply chain, including internal teams, customers, partners and suppliers on a single source of truth. It is enhanced with technical view and labeling of data, augmented reality (AR) visualization, task management (including Kanban card capabilities and tracking) – all on top of a robust and secure data and lifecycle management backbone.

“Organizations gain critical visibility when they integrate engineering, manufacturing, in purchases, historical data and even toolpaths in one solution. The result is shorter quote and delivery times, increased process efficiency, improved product quality and significant cost savings. Zel X replaces disconnected manual processes and point solutions and means less administration, no IT overhead and no additional hardware investment,” says industry analyst Chad Jackson (pictured above), principal analyst and CEO of Lifecycle Insights.

Vuhl sharpen internal and customer collaboration with Zel X

In terms of operations, Zel X has solutions for real-time monitoring and tracking of project and job status with interactive dashboards and specific instructions on the shop floor with notifications available on all devices. As noted above, Zel X also includes tools to assist with automated Request for Quotation (RFQ), both incoming from customers and outgoing to suppliers.

These bits are the kind used by Vuhl, which is a high-performance car manufacturer headquartered in Mexico. The company chose Zel X to complement what it already had in the form of product development solutions from Siemens. With the new solution, they wanted to add support for integration and collaboration with internal teams and customers.

“We serve dozens of different customers, and this has become very complicated to manage. We used spreadsheets, post-it notes on the windows and all these tools that worked but weren’t streamlined in a way that we could communicate across the company. With Zel X, we can integrate everything in one solution. Now we can share data not only on the engineering side, but also with the shop floor and the people who create carbon fiber parts or assemble our sports cars,” says Guillermo Echeverria, co-founder, Vuhl. He continues:

”We use NX, but our customers have many different CAD systems. With Zel X, all the client needs is a browser, and they can open up and view the file you’re working on and highlight it. This has really given us the opportunity to provide better service to our customers. Speed is the name of the game and we achieve that by using the best solutions and software possible.”

Another example on the same track is WashTech, an industrial washing company that specializes in the design and manufacture of machinery for cleaning industrial components and has used Zel X to drive its $1.8 million in annual sales. As WashTech’s founder and director, Mathieu Fresco, explains:

”With Zel X, I can respond to my customers’ inquiries faster and more accurately. Its browser-based CAD/CAM and resource planning tools help us be agile. Our goal is to quote 50% faster and deliver 30% more orders.”

CAD, simulation and CAM

In the intro we mentioned Zel X capabilities in design, simulation and CAM. You thus get access to 3D CAD modeling directly in the browser; this is about streamlined 3D CAD (both direct and history-based modeling) for quote, manufacturing and fixture designs. Industry-leading Parasolid-based data exchange tools combined with Siemens 3D AI-based predictive modeling capabilities allow designers and sales engineers to open and edit imported design data to quickly create designs and drawings, modify existing models or make changes to proposals.

Cloud-based simulation capabilities, based on Siemens Simcenter solutions, allow anyone involved in the design process to quickly perform, regardless of device computing power, simple analyzes to aid direct design decisions. Also part/material selection with optimization.

Zel X is also seamlessly scalable and fully compatible with Siemens mechanical design and simulation solutions, including NX software, Solid Edge software and Simcenter solutions.

Zel X further delivers what Siemens describes as, ”the industry’s first integrated, web-based, CAD/CAM toolset.” Simplified 3D CAD-based programming makes 2.5-axis CAM accessible to designers and engineering staff working on simpler, prismatic parts, with the flexibility to adjust settings or edit G-code from any device as plans change. This also frees up other existing CAM licenses for more complex tasks and is scalable to Siemens’ industry-leading manufacturing solution, NX CAM.

Zel X sharpens the quote process

Bob Schuster, owner of Schuster Mechanical, is a good example of CAD/CAM in the new Siemens environment. The company uses Zel X together with Siemens NX software. He says:

”The goal for us is to start work when we receive the purchase order. In the past, it was difficult to create a good quote and you had to use your best guess. Zel X will improve my quote process to reduce it from weeks to days – even hours.”

“Because I have captured all the steps I used on previous jobs and I can reuse them for my next quote. With Zel X and NX together, I can streamline the manufacturing process and improve the relationship with the customer.”

The Siemens Zel X solution will be available with basic tools to streamline design and manufacturing at a standard level and at an advanced level that adds simulation, more data management capabilities and design tools.

A free 30-day trial is also available.