End-user interest in Simulation Process and Data Management (SPDM) has thus grown quite a bit over the last decade. In the era of digitization, the business advantages of model-based system development processes that work with PLM, digital threads and twins, and that work with other company platforms such as ERP, MES and MRO within the framework of Industry 4.0 concepts are being realized in many places. In general, and with this as background, companies will need to sharpen their management of simulation models, results and relate d design information; which also relates to improving collaboration and reuse; and better integrate simulation activities into the PLM environment.

Ansys has deep technology relationships with both PTC and Aras PLM

The above is generally about values that not least characterize the view that the commercial market leader in the simulation and analysis area, Ansys, embrace. In many cases, the company leads technology development and has also gained a uniquely strong position also as a provider of technology to other players within, for example, the broader PLM area. PLM developer PTC is a great example of this. The company has licensed the Ansys Discovery solution, which has been integrated into PTC’s PLM portfolio (Windchill).

But as noted in the introduction, Ansys also has commercial relationships with other PLM players, eg Aras PLM. Here, however, it is a question of an exchange that goes both ways.

The backdrop is as follows: In 2018, Aras bought the company Comet Solutions. Relatively quickly, this resulted in Aras’ first commercial SPDM release, built on the Aras Innovator platform and with a flexible and multi-fidelity data model, leveraging the integration of Comet’s modeling approach. This took place in Q4, 2020, in connection with a new System Architecture application from Aras.

There are also links to Aras PLM in this. In late 2019, a partnership was established between Aras and Ansys, which made Aras Innovator platform to the foundation of Ansys’ Minerva SPDM offering. In short, Ansys builds its SPDM applications on top of the Aras Innovator platform and delivers that core capability to all of its SPDM customers.

Effective management of simulation data throughout the lifecycle

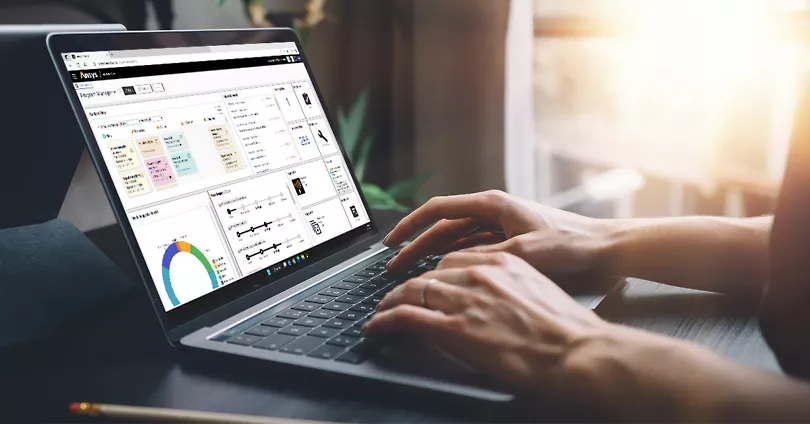

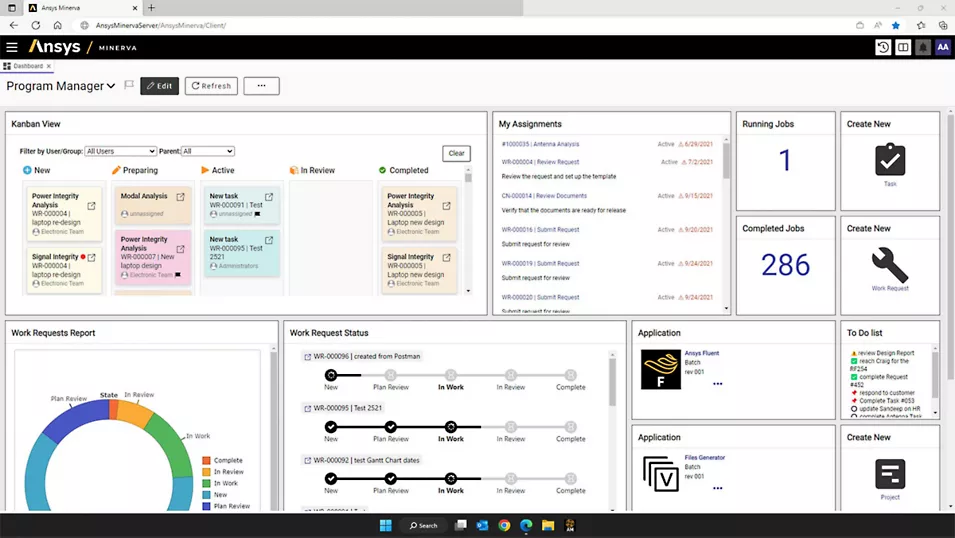

Having said that, Ansys is releasing its new version, 2024 R2, of the Minerva product. In its product launch material, the CAE market leader claims that the simulation process that can be achieved with this data management software, ”enables engineers to effectively manage simulation data throughout the life cycle of a product, streamlining the analysis process, providing insight and aiding decision-making.”

Factors that underpin the credibility of this claim include that with Minerva, you can store, organize and access simulation data not only from Ansys software, but also bring together different simulation tools, making it easier for engineers to access and use them in a single interface. This in turn, Ansys claims, “facilitates efficient organization and management of simulation data, allowing engineers to easily track and access previous analyses.”

One effect of this is that you reduce redundant work and save time. Also, the software promotes collaboration between engineering teams by allowing them to share simulation data, insights and results. Ultimately, this results in better communication and decisions.

“With the 2024 R2 software release, enhancements to the Minerva product give engineers a powerful ability to streamline simulation workflows, ensure accuracy and reliability of results, and more effectively address complex engineering challenges. Engineers can now effectively define, organize, and manage simulation parameters and create a structured way to verify simulation models and results, improving confidence in those results,” it writes, noting that using the Minerva Generic Connector feature provides more flexibility and control over their data, plus improved performance for uploading and downloading simulation data, models and results,” Ansys says in a press release.

Digital Mission Engineering software integrated

Additionally, Ansys notes that the Minerva offering and Ansys Systems Tool Kit (STK) Digital Mission Engineering software are now integrated, and users can open, save and update STK software mission models and simulations directly into their organization’s Minerva ecosystem.

With Minerva’s software version control and traceability of design changes and simulation results, organizations will benefit from this streamlined workflow and disciplined approach to engineering simulation projects and extensive program support.

Moreover, the Minerva offering and Ansys ModelCenter model-based systems engineering software are now integrated, enabling engineers to access and use simulation data and models in the ModelCenter environment, improving workflow automation, data exchange, optimization and decision making.

Simulation parameter management, verification plans and reporting

Here are other high-lights in the new Ansys Minerva version:

- Create a parameter document and manage simulation parameters in a more efficient, standardized way outside of the simulation files. Use the created parameter document as an input file to drive analysis of parameters in engineering simulation applications, such as Ansys optiSLang process integration and design optimization software, the ModelCenter product, and the Ansys Workbench simulation integration platform.

- Integrate verification plans seamlessly into the simulation workflow to validate simulation results.

- Ensure accuracy and reliability of simulation results and confirm that simulations meet pre-defined standards and criteria while providing a common reference point for simulation data, criteria and results and helping identify problems earlier in the workflow.

- Performance improvements for uploads and downloads of simulation data using the Minerva Generic Connector Tool. Upload and download performance is improved for simulation data when using the Minerva Generic Connector feature. Additionally, additional commands are now available when using the Minerva Generic Connector tool.

- Version-controlled folders using newly introduced model classification can help manage the folder structure and critical revision history with ModelCenter software projects or STK software scenarios. These folders are created directly in working mode instead of unchecked. This model is the one created during the Ansys ModelCenter model-based system development software training course.

Integration with the ModelCenter offering and STK software

* Minerva software works with the ModelCenter product and STK software to streamline construction simulation workflows by integrating data management, simulation tools and optimization capabilities.

* Together, Minerva’s software and ModelCenter product provide the ability to access and use simulation data and models in the ModelCenter environment, improving workflow automation, data exchange, optimization and decision making.

* Engineers can run STK software directly from Minerva’s offering and perform an analysis, specify inputs, retrieve outputs and connect the digital wire through many system-level tasks contained in a workflow.

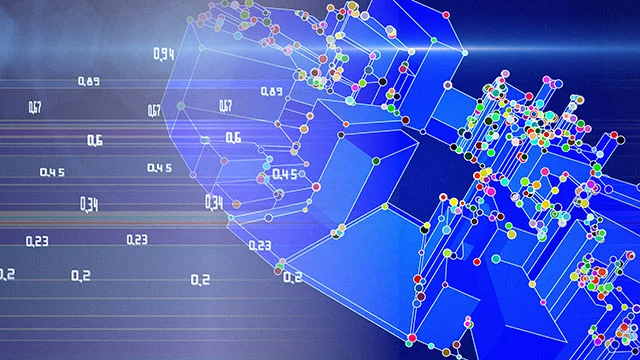

* The Minerva product enables engineers to visualize dependencies between files, tasks and materials, with a central repository to store all data and track, share, visualize and gain insights from past and current simulations.