First the general picture: In Simcenter’s 2310 edition, a number of new functions have arrived. An important underlying objective is to save time at every step of the design process by optimizing workflows and managing complexity to keep pace with innovation. The new release of the Simcenter platform includes Amesim, Flomaster and System Analyst.

The Amesim version is particularly interesting, not least for its connections to battery simulation, or generally anything to do with the utilization of sustainable energy, such as fuel cells in hydrogen operation. With its capabilities Siemens’ solutions can play important roles in the ongoing electrification of the world’s vehicle, aircraft and ship fleets.

Amesim and the ongoing electrification trend

Simcenter Amesim is thus overall a simulation software for modeling and analysis of multi-domain systems, which in system engineering falls within the mechatronics area. The software package consists of a set of tools used to model, analyze and predict the performance of mechatronic systems.

In reality, you can thus handle much of what plays important roles in the ongoing electrification of the world’s vehicle, aircraft and ship fleets. Siemens Digital Industries Software’s Ola Dahlin points out that with the transition to electric operation comes, for example, an increased need to simulate battery concepts, and in cases where the matter is concerned, also the layout of fuel cells where, for example, efficient piping is crucial.

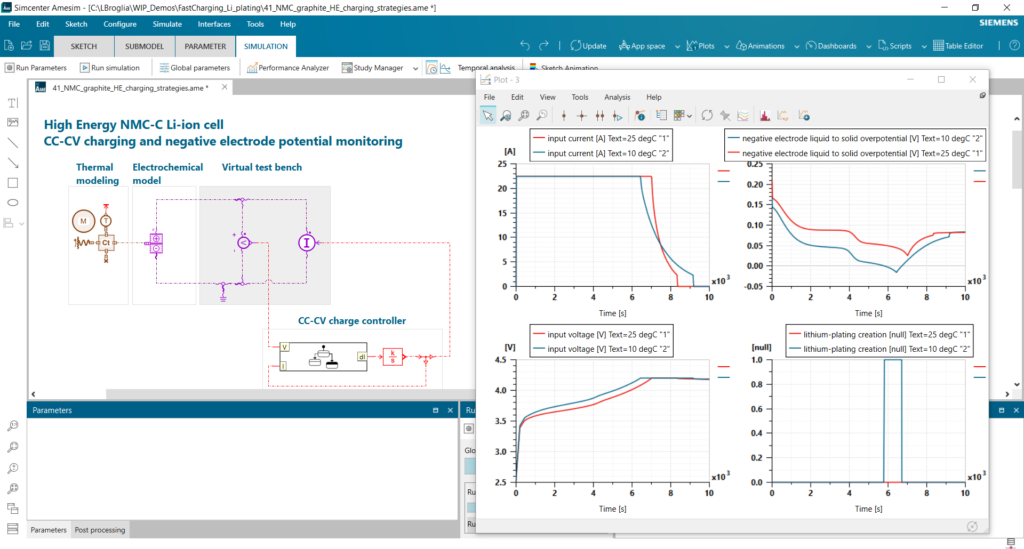

“In Simcenter Amesim 2310 there are several things concerning this, for example an upgraded refined method for particle meshing and a dedicated variable for detection of lithium plating; solutions that help accurately calculate voltage and assess the risk of lithium plating in different a scenarios, including fast charging at different temperatures,” he says.

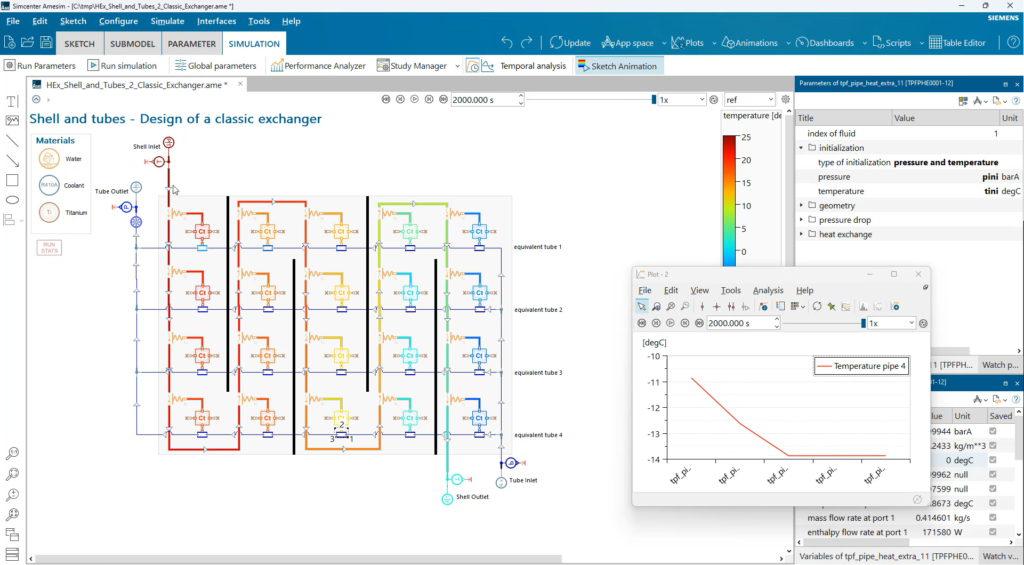

Another exciting piece in Simcenter Amesim is the electrochemical battery model. The new battery heat management system, available in the i 2310 version, is ideal for teams designing heat conduction systems. Here is a clear workflow for designing thermal technology layouts, end-to-end, using advanced integrated tools and resources.

How can Amesim be utilized in this?

“If we take the automotive industry as an example, an engineer can very quickly and easily build up a system model of a complete electric car, from such a model the engineer can then evaluate requirements for, for example, range and performance. When I mean very quickly, we are talking about 10 minutes for our experienced engineers to produce such a model that still gives a good prediction. It is often important to be able to build up different architectures and models early in the development phase even if a lot of detailed information is missing, for example to be able to make early and broad design decisions or simply to have a good idea of the total cost of a driveline project. What the engineers then do is exploit the scalability of Simcenter Amesim and build on their original model with more information as it becomes available, e.g. more detailed data on battery systems, cooling systems or electric motors,” says Dahlin.

What three pieces do you think are the most important when it comes to updating Amesim?

“Traceability of data and requirements is only becoming more and more important so number one I would say is further improved integration between Simcenter Amesim and Teamcenter, the product data backbone in the Xcelerator portfolio, said Dahlin and went on:

“The other important update is the possibility to now also identify the aging model of a battery based on measurement data. There has already been a broad database of battery cells to automatically calibrate battery models with measurement data from the cells, but now engineers can also simulate the aging of batteries in Simcenter Amesim.”

“The last thing concerns fuel cells where, in addition to PEM (a type of polymer electrolyte fuel cell), we have now added the possibility of simulating SOFC (solid oxide fuel cell).”

Simcenter Flomaster is optimized for thermal fluid systems

How would you describe the connections, but also the differences, between Amesim and Flomaster?

“There are of course exceptions here as well, but I would describe the Simcenter Flomaster as being primarily optimized for large thermal fluid systems where the physics itself may not be the primary challenge, but rather the dimension of the system. We can talk about large systems on board submarines or why not the water supply for entire cities. Simcenter Amesim is a full-fledged multi-disciplinary platform for system simulation. Here the focus from us is to create an integration of several different physical disciplines to give engineers who use the tool the opportunity to really understand the synergistic effects between different disciplines,” says Siemens executive portfolio developer and adds:

“The tools are connected through the FMI standard (Functional Mockup Interface), you can for example create something in Simcenter Flomaster ”package” it in a unit that can take the input data you want and generate an output data, you can then read that package in e.g. Simcenter Amesim. This is called FMU (Function Mockup Unit), also a standard that we make sure our tools within Simcenter follow to enable integration in the simplest way.”

Democratization of simulation models

Finally, Simcenter System Analyst has been updated – what is the solution primarily used for and what are the most important improvements?

“The purpose of Simcenter System Analyst is to ”democratize” simulation models, but I think that the tool is perhaps most directly aimed at engineers who do not work with simulation on a daily basis. It is easy to use but it is still possible to do proper and accurate trade-off studies based on existing models created by simulation experts in other groupings. I know several customers where this is very much appreciated by e.g. project managers or design engineers, it leads to better engineering decisions and of course promotes understanding between different engineering teams. I think the most important improvement is that it has become smoother and easier to import models into Simcenter System Analyst, it will increase the productivity and ease of using the tool. In addition, there is now also a large database of existing electric cars that can provide some extra inspiration for how the tool can be used,” concludes Ola Dahlin.

Interesting event around electrification and simulation

For those who want to experience more of the possibilities around Simcenter and related to electrification, where Simcenter Amesim plays a significant role in the tool chain, Ola Dahlin suggests a Siemens-arranged event in Mölndal on March 14th. The topic revolves around electrification and has presentations and case studies about this with leading experts from Siemens and prominent customers.

Link for those who want to register:

Navigating the challenges in electrification (canva.site)