It is clear that some modernizations in PLM technology will come with the CATIA purchase for example for Volvo Cars, including some functionalities related to the changes in the digital tool sets needed to manage the electrification of the vehicle models and the trend towards the increasing importance of software in the context of SDV-concepts (Software Driven Vehicles).

Sappin mentioned that Volvo Cars was among the new contracts secured, ”after a thorough evaluation of the system.”

Extends the bet on CATIA

After speaking to people inside Volvo Cars a qualified guess is that what the company has signed up for is an extension of the 3DEXPERIENCES V5 solutions and some modernizations. There have been certain parts of the company that spoke in favor of changing the system, while those that wanted to remain in the mainly V5 environment so far drew the longest stand. As always, there is a degree of conservatism in these contexts, where concerns about possible technical difficulties, problems associated with migration of older data, and reduced initial productivity during the early phases of the learning curve, can act as deterrents to a switch.

It is also clear that Siemens Digital Industries Software’s PLM and cPDm platform, Teamcenter, remains as the database backbone. A bit of a status quo of existing setups then, with the addition of things related to SDV (Software Defined Vehicles), software and battery/electrification related management.

Virtual twins and system modeling

What is interesting to note is that Dassault Systemes nowadays does not talk about the V6 version of its platform, preferring instead to generally talk about the 3DEXPERIENCE platform; which means that customers are often using the older V5 version, alternatively leveraging parts of the V6 version in combination with V5, where there are gains to be made that do not come at a cost in terms of compatibility or productivity issues.

At the customer level, customers are probably interested to look at things that the V6 version can add, as well as introducing functions in the V6 environment that can be brought in without affecting the capabilities of the V5 setups they already have.

In any case, apart from this, Sappin stated that the company’s development of solutions around virtual twins has taken CATIA and 3DX to the absolute technological cutting edge forefront.

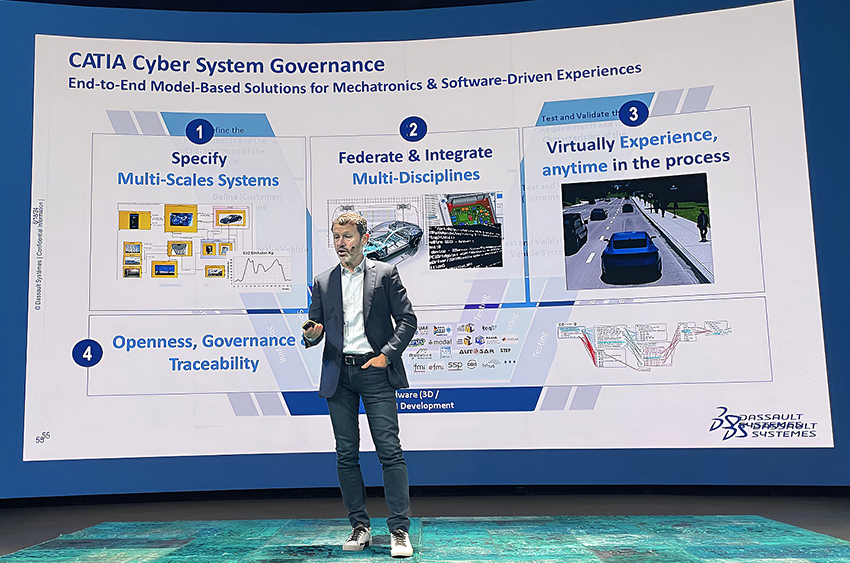

“Everything is connected with virtual twins and system modeling,” Sappin claimed and also pointed to the importance of MODSIM and simulation: ”MODSIM enables simulation to drive the entire product development process from start to finish, from requirements to architecture, from validation to certification and from product development to program management, including design exploration, processes, automation, change management and collaboration,” summed up Olivier Sappin.

From the stage in the Space Arena, the CATIA director also highlighted the company’s collaboration with the German specialist Bosch regarding the SDV part.

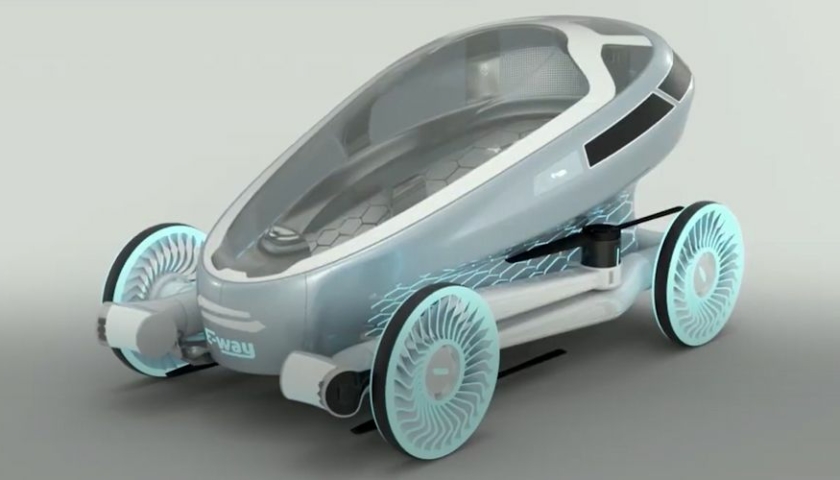

Moreover, an interesting concept that Olivier Sappin covered was the production of the so-called ”E-way Rescue Roadster”. This is a concept for an autonomous rescue vehicle, with built-in drone-flight capabilities, developed using Dassault’s 3DEXPERIENCE platform on the cloud, and which demonstrates how different disciplines in development teams can collaborate widely in the 3DEXPERIENCE environment.

“The platform on the cloud is fundamental for designing in a collaborative way of working,” he said and added that, “Vehicles of this nature are challenging and require multidisciplinary systems. Even though everyone is working in their own area of expertise, every decision made affects other subsystems, which in turn requires broader platform capabilities.”

It is not difficult to agree with this. The challenge in optimizing a complex system is to find the best compromises according to requirements for, among other things, structure, loads, position and internal volume. Studying these constraints is inherently interdisciplinary and requires high-performance design, digital simulation and collaboration tools, in which Sappin believes the 3DEXPERIENCE platform is the best enabler.

The background is that, when the Covid pandemic reached its peak, DS had a collaborative team, consisting of a product designer, mechanical engineer and medical doctor, come up with a practical solution to quickly and safely transport patients from home to hospital. That’s how the concept of an autonomous flying rescue vehicle was born.

Related to this, Dassault’s CATIA chief mentioned that the use of the cloud platform has already taken off within Dassault Systeme’s various customer groups.

“We currently have more than 135,000 users of 3DEXPERIENCE Cloud SaaS,” said Sappin.

Sustainability: The value of a circular approach

As noted in the introduction sustainability was one of the main areas for TECHNIA’s Innovation Forum event, which was well reflected during the opening presentations by Linn Lindfred, founder of the company Circularista. Lindfred argued, supported by, among other facts, the World Economic Forum’s Risk Report 2023-24, that a circular approach is the way forward to deal with waste, overproduction and industrial waste. In this, PLM, AI and simulation technologies play important roles as enablers.

“Today’s customers want and demand visibility over the entire chain and consequences in all stages of a product’s life,” she said and added: ”Back up what you as producers have to say with real data. Inform about things such as materials, which can be of utmost importance when reusing products or product content.”

Lindfred also exemplified the benefit through a project for the real estate company Humlegården where, with the help of Circular Office Adaptation, CO2 emissions were reduced by 68%, the consumption of building materials by 66% and a total success in reducing the cost picture by 35%.

“PLM technology is needed to scale systems,” she added. “As is digitalization.”

AI as an enabler rather than a threat

But the event was also filled with other interesting speakers, presentations and technology tracks, such as Julie Holmes, technology and innovation expert and well-known event speaker, who talked about how AI will reshape innovation.

“AI is revolutionizing the way we work,” she claimed and pointed to factors that can support a positive productivity development:

* Increase your productivity: Imagine a tireless intern managing your calendar, prioritizing emails and even suggesting replies. AI tools make this a reality, freeing up your time for strategic thinking (“or, you know, that afternoon walk your dog has been asking for since breakfast”).

* Data-driven decisions: Take the guesswork out! AI can analyze massive amounts of data to provide valuable insights that inform your business decisions. It’s like having a crystal ball powered by information.

* Sharpened customer service: AI-powered chatbots and platforms are on the front lines 24/7, ensuring your customers get fast and helpful support. After all, 69% of customers prefer to solve problems independently before contacting support. And satisfied customers are loyal customers.

* Automate and optimize: AI can streamline repetitive tasks and optimize operations, making your business run smoother than ever. It is the silent hero behind the scenes, increasing efficiency.

* Continuous learning: AI continues to learn and evolve along with your business. You always have access to the latest tools and strategies to stay one step ahead. Just remember to find the balance between BASIC, BLENDED and BESPOKE AI tools.

Some other customer cases in Dassault/TECHNIA environments

Other interesting speakers and also representative users of various 3DEXPERIENCE tools during the event were, among others:

- An always exiting acquaintance during Dassault Systemes and TECHNIA event is Mölnycke Health Care, also a 3DX user. Anna M. Windevall, Jakob Turesson and Staffan Bröte talked about how they work to partly future-proof the company’s PLM strategies and how to secure a good ROI (Return on Investment).

- Speaking of GE Health Care, Cytiva’s Lars Lövström Nord, Global head of PLM Processes and Tools and Hans Sjöbom, Business Manager at the company were on site and discussed the company’s digital transformation. Cytiva is a global provider of technologies and services that advance and accelerate the development and manufacture of medicines. The company’s products are used in both research and manufacturing of, among other things, the medicines against covid-19. The company was previously called GE Healtcare Life Sciences, but was sold in 2019 to the American company Danaher Corporation, which continues operations under the name Cytiva.

In this context, Sjöbom is responsible for maintenance and development of the company’s PLM/cPDm system (”collaborative Product Definition management”), ENOVIA, while Lövström Nord works strategically with business partners to create greater value by developing PLM platforms that enable cross-border collaboration , which digitally reduces the distance between business functions. His long-term mission is to drive customer satisfaction, innovation and growth by providing standardized and scalable PLM processes and tools that support simplification, quality and compliance, enabling increased business agility.