The idea is that ProPlanAI should ”learn” from the data created by a company’s CAM programmer. This, Hexagon believes, will enable manufacturers to automatically explore existing programming information to predict ideal results tailored to a company’s preferences, production capacity and needs. The solution will be available within Hexagon’s CAM software and powered by Nexus. Chuck Mathews claims that ProPlanAI will continuously learn and adapt, to ensure that the programs are as efficient and productive as possible.

“Because manufacturers use their own pool of data to build programs, proposals automatically reflect the knowledge and experience of individual companies, as well as the parts they produce and the machine tools they use. This ensures that new employees can quickly get up to speed, while also ensuring that there is no knowledge spillover when a person leaves a company or retires – something that is crucial in an industry facing skills shortages,” he says.

AI powered chat support

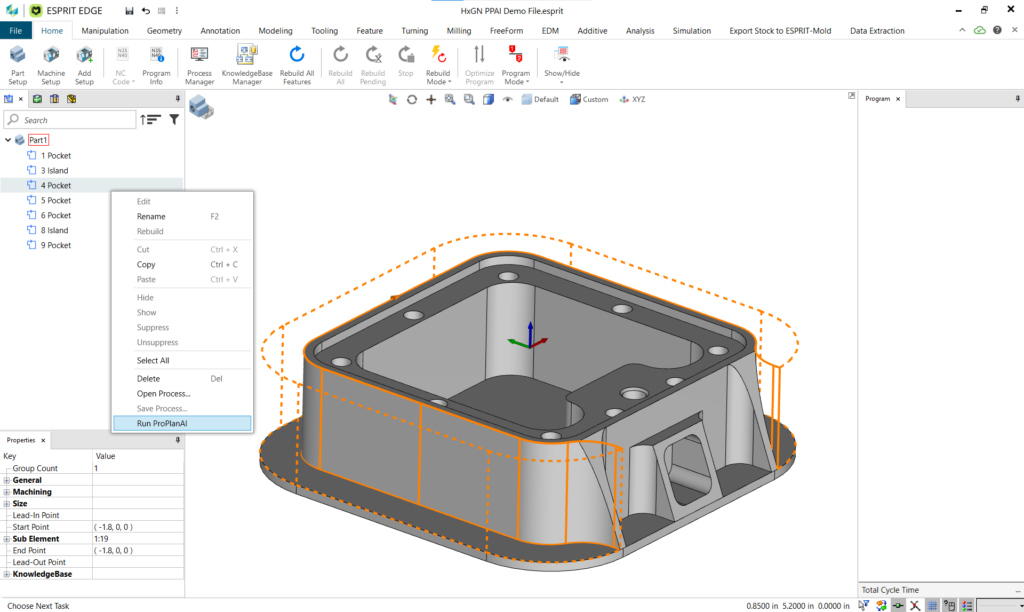

Furthermore, ProPlanAI will also feature a co-pilot that can guide people through the process of setting up a machine and present them with programs that work. In addition to offering support and guidance – for example, tips on how to use the software, processes for making a specific del and the best processing strategy to use – users can use chat functionality to ask specific questions and launch commands.

ProPlanAI has already been beta-tested by several industry experts, including RODIN Machining, which is moving towards fully unmanned production for milling, turning, gripper and material handling, loading and unloading machines, and tool change.

Paul Mooij, Director of Digital, at the company RODIN machining commented on the matter as follows:

“We set out to build the first autonomous factory in 2022 and we make extensive use of automation, but machine tool programming is complicated and requires experience. What makes ProPlanAI exciting is that we can leverage our human capital to achieve greater machine utilization – our team can program machines in a fraction of the time by applying their valuable skills in monitoring ProPlanAI proposals and finalizing program specifications.”

In addition to streamlining part programming, the technology can potentially help companies identify latent standard practices, provide notification of deviations from company programming practicies, and better utilize product manufacturing information (PMI) embedded in design files for even more automated CNC programming.

Strategic partnership with Microsoft

Furthermore, it can be noted that the announcement of ProPLanAI builds on Hexagon’s strategic partnership with Microsoft to redefine manufacturing with cloud technology, which was announced in April 2024.

”Microsoft’s collaboration with Hexagon is driven by a shared belief that we can transform manufacturing productivity. It’s rewarding for us to see how the AI capabilities provided by Azure bring productivity-enhancing automation to expert CNC programmers, while helping new users develop faster. This is exactly the kind of transformation AI can bring to the industry, and we’re excited to see Hexagon use its manufacturing expertise to transform workplace productivity throughout the value chain with its Nexus platform,” summed up Clare Barclay, President, Enterprise and Industry, at Microsoft EMEA.