One of the most exciting news in the updated NX version 2406 is as mentioned above the immersive solutions.

”Yes, the new ’Immersive Explorer’ is a revolutionary VR application,” says Rolf Emdevik. ”It can be used for early concept evaluation of e.g. moving animations made in ’NX mechatronics designer’, as well as for classical design review. The realism and feeling have reached new levels as you now visualize realistic material definitions and support more and more developed headsets that provide a completely new computer game-like experience.”

Why the new ”Immersive Explorer” is super interesting

It is undeniably a sign of the times that ’Immersive Explorer’ is being promoted as a big deal by Siemens – why? A heavy point with immersive design is that the technology via a head-mounted display gives the user a strong experience of really being in the world, or around and in the product they are looking at–for example a digital factory or a 3D-model of a vehicle. What is presented, and how one moves in the digital environment, is perceived as real.

”In a sharp software, you can then in real time examine, train on related moments and even correct, a series of details, constructions and functions, in the model. This is what the future looks like for immersive engineering,” says Rolf Emdevik, adding that in the new industrial metaverse concept, this type of technologies will play important roles, not least in distributed environments, where parts of development teams are located in different places.

”In an immersive session, experiences can be shared in real time by participants who all see the same things. Regardless of whether they are in Paris, Gothenburg or Berlin, for example.”

Launched in December 2024, NX Immersive Explorer supports all major HMD hardware options. With its capabilities, such as the ability to focus on specific parts of assemblies, examine individual components, and add markups and notes to document outcomes for design review, the design process can be done in a whole new perspective.

It will be very interesting to follow how this solution is received by the user collective.

AI-enabled design tools

In the intro we noted the development of the AI side and the reflections of this in the new updated NX. AI is everywhere, helping to improve and accelerate processes with NX’s artificial intelligence-enabled design tools. New such AI-enabled tools include topology optimization, ’Performance Predictor’ and gyroid modelling, which connect to existing tools such as command prediction and selection prediction. This contributes to increasing the efficiency of the design work.

The ‘Performance Predictor’ is an AI-enabled design simulation tool that focuses on validating material selection and mechanical performance of individual parts – enabling designers to validate tests and repeat design iterations in real-time. Of course, this also contributes to speeding up the innovation process and also helps to eliminate costly errors.

Combined with AI-enabled topology optimization and new gyroid lattice and infill design capabilities and the ‘Design Space Explorer’ capability introduced in 2023, this enables users to create optimal parts that not only perform as needed, but also allow them to perform lightweight studies and draw advantage of additive manufacturing where appropriate.

Rolf Emdevik goes on to point out on the AI side how Siemens continued to work on sharpening user interaction.

”Yes, when it comes to UI (User Interface) we are working hard on improving user interaction. For example, with our AI-based sketcher, the already highly appreciated ’logic editor-UI’ for codeless automation, which not least supports the MBD (Model-Based Design) processes, creates new more competent ’Deformable Components’ (springs, O-rings etc.) and advanced geometries with algorithm modeling as a few well-chosen examples.”

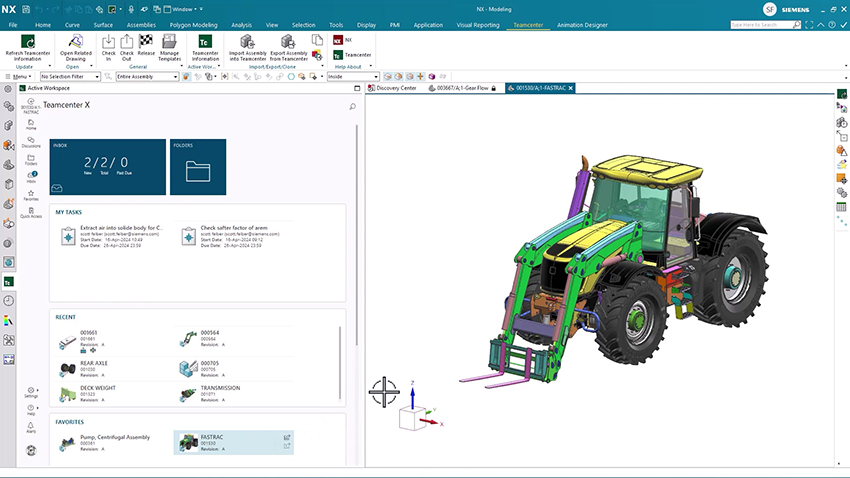

NX X and design work in the cloud

Undeniably, the AI trend has set in motion an almost explosive development related to design work. Something that also applies to the development of working in cloud environments. In parallel with Siemens launching the new updates in NX ”classic” CAD, as noted in the intro, the cloud variant of this CAD solution is now also coming in an increasingly complete set.

NX X offered in the cloud has been enhanced with built-in data management based on Siemens’ market-leading cPDm software (collaborative Product Definition management, ”PLM/PDM”) Teamcenter. With information stored on Siemens’ secure cloud Software-as-a-Service infrastructure, customers can unlock a new level of NX that offers more flexibility, scalability and collaboration.

”This is extremely exciting,” comments Rolf Emdevik. ”NX X looks and works exactly as we know it today. The difference is that new and existing–quick-footed customers–can benefit from a system completely managed by Siemens, this means eliminated need to purchase hardware, no resource-intensive upgrades, extremely flexible license management with Siemens ”Value Based Licensing”, where the customer has access to almost all licenses that Siemens NX can offer.”

Speaking of which, Emdevik also teases another interesting piece of news, the ZEL X. What is this?

”ZEL X is a cloud application that runs directly in a web browser and is largely based on the same technology as NX, but with new innovative ways to work more efficiently with, for example, AI driven predictive modelling,” he says, and continues: ”In addition to CAD, ZEL X supports both CAM and CAE. The idea here is to have a cost-effective solution that is also very quick to learn and implement. And the nice thing is that you can combine work processes between NX and ZEL X, as the file format is the same.”

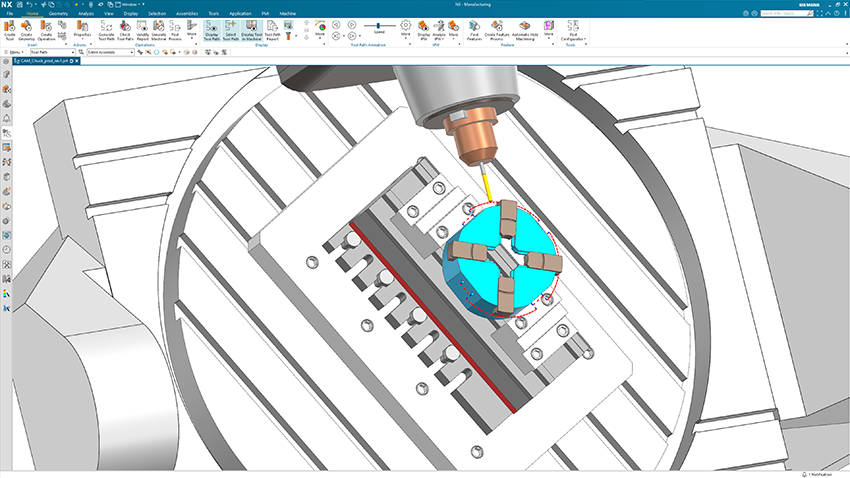

What happens in terms of the manufacturing connections?

This said, let’s look at what happened in terms of the connections to the manufacturing side, where also very interesting things have occured:

”Absolutely,” says Emdevik, ”perhaps above all on the AM (Additive Manufacturing) side, where we benefit from our broad product portfolio within CAD, CAM, CAE. We support the entire AM flow from topology optimization, simulation of the print process and print preparation where we benefit from working with exact geometry instead of faceted ditto that most of our competitors have to rely on. This provides valuable opportunities such as CAD created ’user defined’ support structures, full control of the print operation with evaluation of deformation and compensation of this, down to final processing of the model where our proven NX CAM application completes the job.”

In short, this update brings higher levels of user control and workflow productivity to NX CAM and NX Additive Manufacturing (AM) enabling users to move from detailed design to high-quality components faster and with greater confidence. Enhanced 3D Adaptive Roughing, a high-speed machining strategy, now helps programmers automatically specify starting locations, resulting in more efficient machining and longer tool life. Similarly, the punching operation has been improved to provide better control over tool movements ensuring safe machining and improved surface quality. In addition, the Cloud Connect Tool Manager has been upgraded to streamline CNC programming. This tool data management feature with direct access to tool supplier catalogs now enables the association of machining settings with cutting tools, resulting in faster programming.

Workflows to prepare additive manufacturing build jobs for metal and polymer parts have been streamlined with new features and improvements. New facet selection methods simplify the creation of support structures for parts modeled with facet geometry. In addition, new functions for ’subnesting’, sinter box creation, wafer area distribution calculation and 3D packing optimization greatly simplify and accelerate the workflow for preparing polymer-built jobs. In addition, new Siemens-built processors simplify the generation and output of print job files from NX to SLM Solutions and Trumpf metal 3D printers. Finally, new multi-axis additive build rules enable the creation and reuse of custom process parameters, often considered the “secret sauce” to achieving consistent, high-quality builds.

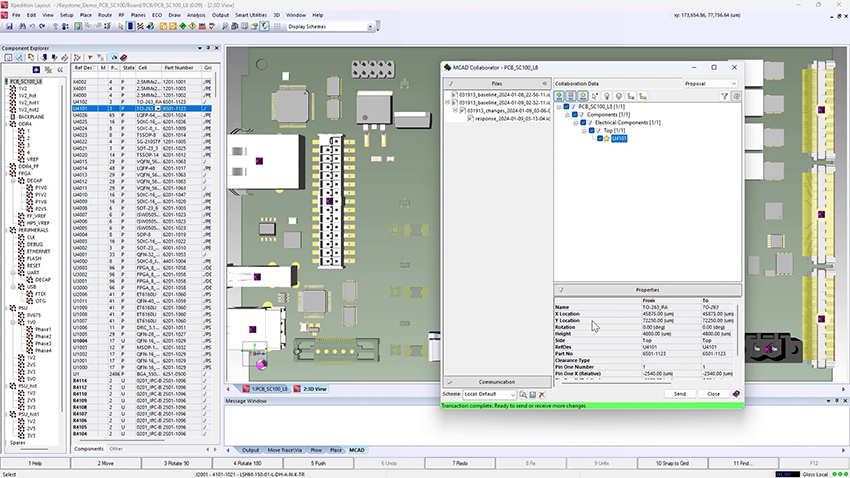

Improvements for the electrical and semiconductor industry

Finally, also a few words about the electronics area. As such, the E/E side (electrical and electronic systems development) is one of Siemens Digital Industries Software’s strongest strengths. Which is about indispensable digital tools for developing sophisticated electronics-based solutions. Here, Siemens’ rich portfolio capabilities are now also spreading to the CAD suite.

The new Managed Environment for Electronics Design is a continuous digital thread that connects data from various software from the Siemens Xcelerator platform – including NX, Capital software (E/E), Xpedition software for PCB design and Teamcenter for PLM – enabling improved integration between the four, enabling seamless data flow and collaboration between electronic and mechanical design teams. This unified data management platform for electrical/electronic and mechanical domains simplifies ECAD and MCAD processes.

Alongside this there are quite a few updates regarding NX and BIM (building information modelling). A lot has happened here as well, but that’s another story that will get its own article.