Oswald Deuchar further states that the extension of the life cycle now achieved, ”supports NASA’s operational goals, while the upgrade of the variable drive’s key components demonstrates efficiency and a circular strategy.”

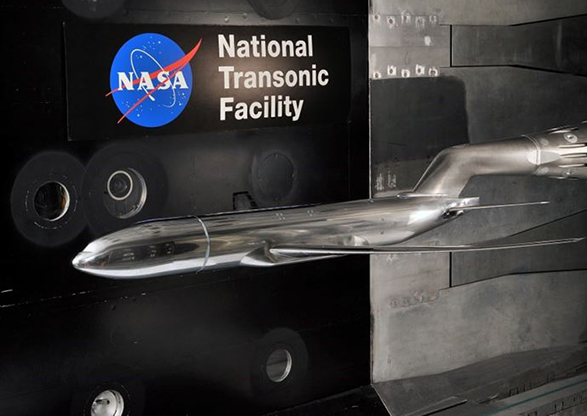

The NTF wind tunnel is located at the Langley Research Center in Hampton, Virginia, USA.

Powerful electronic components

After ABB’s service specialists evaluated the performance and mechanical connections of the existing drive, the next step was to develop a solution based on modern high-efficiency power electronic components to match the original drive’s maximum power, while achieving high availability and reliability. This resulted in the modernization of the drive, to replace key components inside the existing footprint with the latest ABB state-of-art technology. The scope included upgrading the small part of the drive (control unit), which minimized the duration and disruption of the project and demonstrated circularity by minimizing waste and logistics as much as possible.

A VSD controls the speed and torque of an AC motor by converting fixed frequency and voltage input to a variable frequency and voltage output. System performance can be greatly improved by controlling speed to precisely match the load. A VSD – the most common area of use for pumps and fans, essential elements in wind tunnels – controls the speed of the electric motor by changing the frequency of the mains from the usual 50 Hz to a higher one, upwards of 65 Hz, or lower, downwards 5–10 Hz. ABB has generally frequency converters for motors from 0.18 kW to 5.6 MW. But in the case of the NTF tunnel, we are talking about completely different levels – one of the world’s largest at 101 MW.

NASA has ordered the upgrade project as the first within the framework of the service agreement ABB Motion OneCare, which includes spare parts and maintenance. Similar agreements give operators like NASA the flexibility to combine desired services to optimize the life cycle of their engines, generators and drives.

Finally, a couple of words on the Reynolds number. It is used to classify the state of flow. The Reynolds Number Demonstration is a classic experiment, based on visualizing flow behavior by slowly and steadily injecting dye into a pipe. This experiment was first performed by Osborne Reynolds in the late nineteenth century.