“Digitalization and automation – including the use of robotic technologies – are not only crucial for improving productivity, reliability, flexibility and sustainability, but are also important drivers in the development of smart factories,” comments Juntian Dong, Partner and Head of Industrial Goods, at Porsche Consulting China.

Dong further adds that, ”global EMS companies are facing a range of challenges, from supply chain disruptions and lack of skilled labor to a need for more flexible processes and the pressure to demonstrate greater circularity in operations.” Something that is highly relevant capabilities in light of the general global security development of recent years.

Maximizes the finish

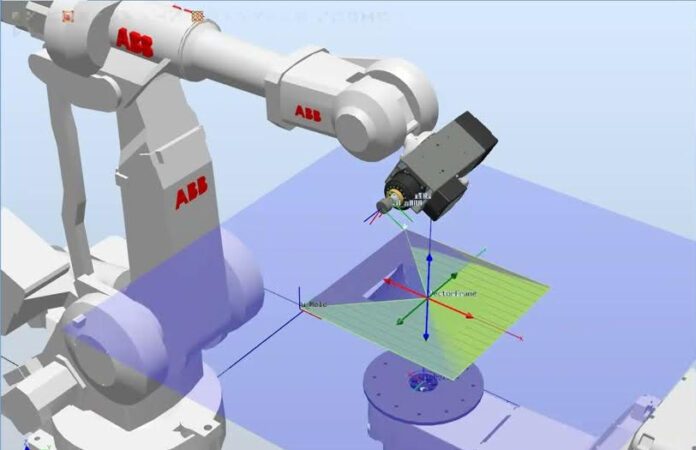

The report highlights the use of robotic grinding and polishing in modern electronics manufacturing, where the technology is used to maximize the finish of consumer products such as smartphones. It explains how the finishing of robots is often compromised by complicated programming tools used offline and associated problems. Discrepancies can also occur when virtual robot code is transferred to physical code, leading to defects that require time-consuming manual fine-tuning to correct them, especially for 3D geometry. From an operational and commercial perspective, the challenges lead to higher construction costs for electronics manufacturers, as well as a high reliance on expert resources, reduced product yield and increased waste.

The report explains how these obstacles are solved by ABB Machining PowerPac, which is part of ABB’s market-leading RobotStudio suite of offline programming tools. With Machining PowerPac can automatically generate CAD path codes, providing an accurate representation of actual component surfaces and eliminating the time-consuming traditional point-by-point commissioning process.

Improvements with Machining PowerPac

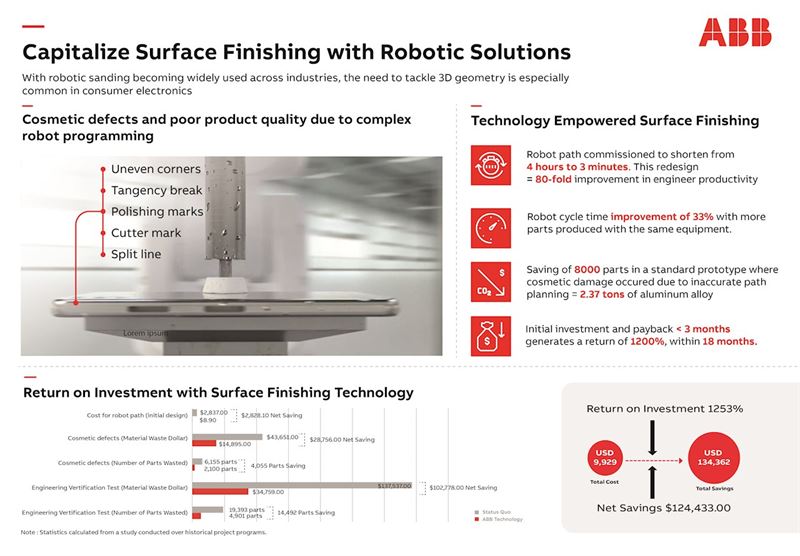

The report uses the results of a study of historical project programs to demonstrate the improvements Machining PowerPac can deliver. It includes significant reductions in the time required to generate a robot path – from four hours to three minutes – and improvements in robot cycle time of up to 33 percent, meaning more components can be produced with the same equipment.

Other points include potential savings of 8,000 prototypes due to reduced cosmetic damage from track design flaws, equivalent to 2.37 tons of aluminum alloys. These improvements in time, quality and productivity, along with additional savings in materials and energy, have allowed investments made in Machining PowerPac to pay for themselves often in three months with an estimated return on invested capital of over 1,200 percent over 18 months.

The report is available free of charge here https://campaign-ra.abb.com/l/961042/2024-08-15/5slwcyconcurrent design, rules, relationships and automation.